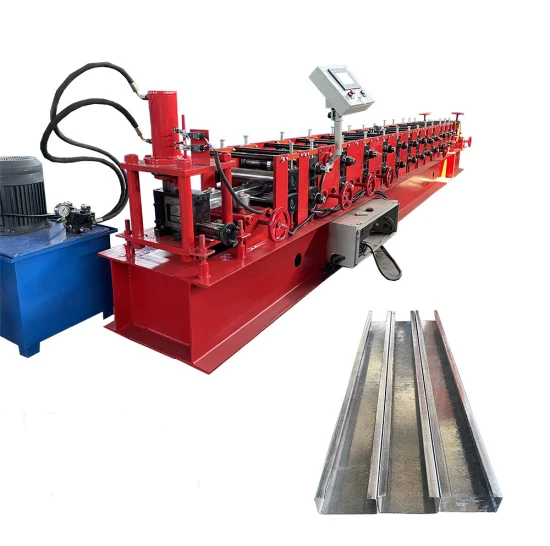

Curving Roof Panel Cold Metal Sheet Roof Building Roll Forming Machine

Bohai Arch Roof Roll Forming Machine Technical Parameter 914-610 Related Production Characteristics Machine PhotoMachine

Description

Basic Info

| Model NO. | 914-610 |

| Material of Cutting Blade | Cr12 MOV |

| Material of Roller Shaft | 45# Steel, Galvanized |

| Material of Rollers | 45# Steel, Quenched with Hard Chrome |

| Type of Cutting | Roll-Formed and Length-Set Cutting |

| Proper Span | 6-38m |

| Transport Package | Packed in Container |

| Specification | 11650mm*2230mm*2300mm |

| Trademark | BOHAI |

| Origin | Liaoning Province of China |

| HS Code | 8455229090 |

| Production Capacity | 20 Sets/Year |

Product Description

Bohai Arch Roof Roll Forming MachineTechnical Parameter 914-610

| Production Name | Bohai Arch Roof Roll Forming Machine |

| Size | 11650mm X 2230mm X 2300mm (With Single Axle 4 Tires) |

| Total Weight | About 15 Ton |

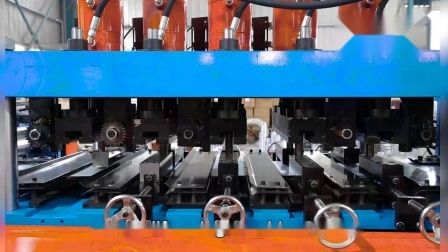

| Thickness of Bending Leaf | 10mm thickness, processed by CNC |

| Cutting Blade | 12CrMov Material, Heat Treatment |

| Cutting Type | Mechanical Cutting |

| Forming Type | Roll-Formed and Length-Set Cutting |

| Power | Total Motor Power : 17.9KWMain Motor Power : 7.5KWBending Power : 3.0KW+1.1KWx2Cutting Power : 3.0KW |

| Seaming Power | 1.1KW+1.1KW |

| Roller Material | 45# High-Quality Steel, Quenched HRC 55~65, Hard Chrome Plating |

| Shaft Material | 45# High-Quality Steel, Galvanized |

| Stand of Molding | 13+1 Steps |

| Feeding Width | 914mm |

| Effective Width | 610mm |

| Using Rate | 66.7% |

| Thickness Coil | 0.5-1.6mm |

| Speed | Forming Part : 15m/minBending Part: 13m/minSeaming Part: 16m/min |

| Suitable Span | 6~38m |

| De-Coiler | Inner-Diameter of Coil : 450mm ~ 650mm, Max Width of Coil : 914mm ~ 934mm Load : 10Ton |

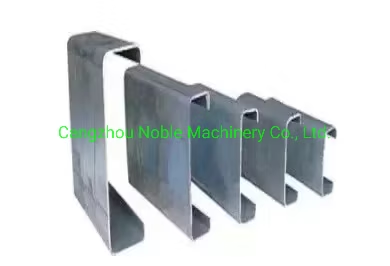

| Model | Feeding Width | Effective Width | Thickness Coil | Largest Span |

| BH-600-300 | 600mm | 300mm | 0.5-1.6mm | 30 |

| BH-600-305 | 600mm | 305mm | 0.5-1.6mm | 28 |

| BH-914-400 | 914mm | 400mm | 0.5-1.6mm | 40 |

| BH-914-610 | 914mm | 610mm | 0.5-1.6mm | 38 |

| BH-914-650 | 914mm | 650mm | 0.5-1.6mm | 26 |

| BH-914-700 | 914mm | 700mm | 0.5-1.6mm | 22 |

| BH-914-750 | 914mm | 750mm | 0.5-1.6mm | 14 |

| BH-1000-610 | 1000mm | 610mm | 0.5-1.6mm | 42 |

| BH-1000-680 | 1000mm | 680mm | 0.5-1.6mm | 38 |

| BH-1000-700 | 1000mm | 700mm | 0.5-1.6mm | 30 |

| BH-1000-750 | 1000mm | 750mm | 0.5-1.6mm | 24 |

| BH-1000-800 | 1000mm | 800mm | 0.5-1.6mm | 18 |

| BH-1200-800 | 1200mm | 800mm | 0.5-1.6mm | 40 |

| BH-1220-800 | 1220mm | 800mm | 0.5-1.6mm | 42 |

| BH-1250-800 | 1250mm | 800mm | 0.5-1.6mm | 45 |

Characteristics

- The rollers and shafts are both solid, the rollers are made by 45# steel plated with hard chromium.

- The thickness of our arch shaping leaf is 10mm, the process of manufacture for our arch shaping leafs are controlled by computer.

- The length of the finished sheet is measured by the electronic measurement instrument or mechanical measurement instrument.

- Our machine can be divided in to two cutting ways, one is hydraulic, and the other is mechanical. Controlling system include manual and automatic. It can be also designed according to your requirement.

- Our helping hand wheel and the counter are used in adjustment of the bending of arch sheet, which makes the operation simpler.

- Our hoisting tool is light and handy; the weight of hoisting tool of our company is 2KG. It is convenient to install and uninstall the hoisting tool. Its hoisting speed is quick.

FAQQ: Can you make the machine according to my design or photo type?

A: Yes, we have an experienced team for working out the most suitable design and production plan for the machine according to your demand or photo type that you are going to book with us.

Q: Are you a factory or trading company?

A: We are a factory located in YingKou city, LiaoNing Province, China. Our city is near Beijing. All clients from abroad and home are warmly welcome to visit our factory!

Q: How do you guarantee the quality of the products?

A: Every section of our production has strict manufacture process, than professional inspectors check every section of the production, next the production will work for testing quality, which must be 100% quality assurance. Unqualified resolute don't a better factory.

Q: What is your service?

A: We provide the technical support for whole life. Pre-sales service includes inquiry and design support and view our factory. After-sales service includes training how to instal the machine, training how to use the machine, and engineers available to service machinery overseas.

Cooperation

| Step 1: Tell us your requirements. |

| Step 2: Quoataion will be sent based on your requirement. Solution will be recommended to you as the alternative. |

| Step 3: Negotiate and confrim each details for goods, trading terms and so on, get agreement and sign contract. |

| Step 4: Advanced payment and production. |

| Step 5: Factory examine goods/ rectify and reform to meet the requirements of contract. |

| Step 6: Balance payment and shipping. |

| Step 7: Handing shipping files to help clients get goods from transporter in time. |

| Step 8: Clients get goods and go into warranty time. |

| Step 9: Provide overseas service for clients. |

Our Contact

Send now