Rolling Shutter Door Roll Forming Machine

Package size per unit product 550.00cm * 100.00cm * 130.00cm Gross weight per unit product 3000.000kg Rolling Shutter Do

Description

Basic Info

| Model NO. | LW18-127-180 |

| Certification | CE, ISO |

| Condition | New |

| Customized | Customized |

| Usage | Roof |

| Transmission Method | Electric |

| Name | Rolling Shutter Door Roll Forming Machine |

| Production Speed | 12-18m/Min |

| PLC | Panasonic/Siemens/Delta |

| Touch Screen | French/English/Spanish/Portuguese/Russian |

| Application | Roller Shutter Door |

| Feeding Material | PPGI, Aluminium, Prepainted, Galvanized, Aluzinc |

| Machine Type | Cold Roll Forming Machine |

| Profile Drawing | Customized as Your Required |

| Voltage | 220V/380V/415V or as Your Request |

| Encoder | Omron |

| Electric Components | Delixi or Chnt |

| Suitable Thickness | 0.3-0.8mm or as Your Request |

| Inverter | Saj or Delta |

| Driving Motor | Lichao, Shanghai |

| Cutting Blade | Cr12MOV |

| Transport Package | Plastic Film & Steel Wire Fixed |

| Specification | 6200mm*1000mm*1400mm(L*W*H) |

| Trademark | Chicheng |

| Origin | China |

| HS Code | 8455221000 |

| Production Capacity | 30sets/Month |

Packaging & Delivery

Package size per unit product 550.00cm * 100.00cm * 130.00cm Gross weight per unit product 3000.000kgProduct Description

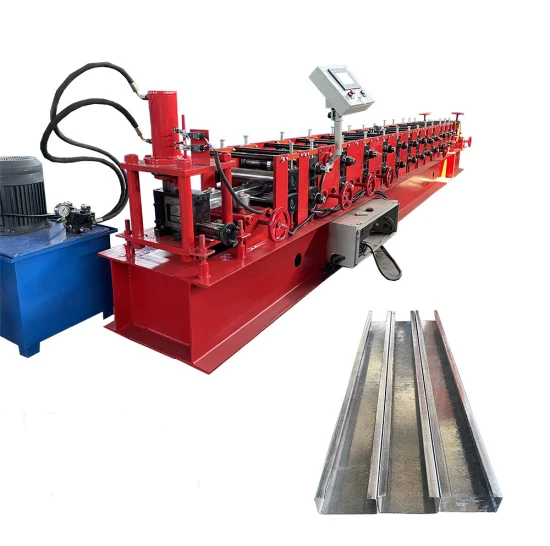

Rolling Shutter Door Roll Forming Machine

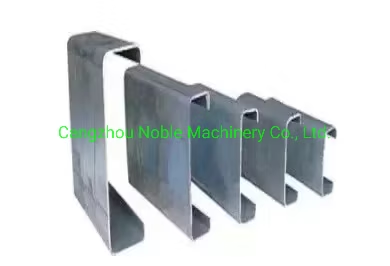

A. High PrecisionB. High EfficiencyC. Customized ServiceD. Low NoiseRolling Shutter Door Roll Forming Machine is the most popular type of roll forming machines, mainly suitable for PPGI, GI and other harder coils. It makes different shape of color steel roof sheet, which is used in the construction of various industrial plants, buildings, factory, villages, warehouses, supermarkets, hotels, exhibition, shopping malls, shutter doors and ect. The finished sheet usually worked for roof and wall panel. It has beautiful design, and widely used in all over the world.

We adopt export standard technical solution to make the machine strong and stable enough. Usually it can run with the normal speed to 15m/min, high speed to 25m/min, max speed to 30m/min. PLC with touch screen operation make the machine simple and easy for operation.1. Production Process Diagram: Uncoiling --- Feeding --- Roll Forming --- PLC Controlling --- Hydraulic Pressing --- Length to Cutting --- Receiving 2. Main Technical Specifications:

| Name | Rolling Shutter Door Roll Forming Machine | |

| Raw Material | Material | PPGI PPGL GI GL |

| Width | 1000/1200/1250mm | |

| Thickness | 0.8-1.2mm, customized | |

| Power Required | Power | 380V 3Phase 50Hz, customized |

| Main Motor | 5.5KW, servo motor driving | |

| Cutting Motor | 4.0KW, Lichao, Shanghai/Siemens Brand | |

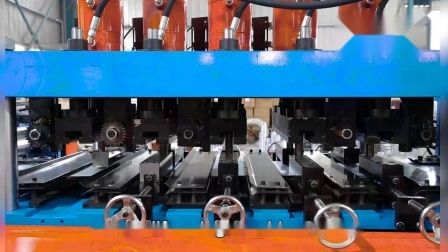

| Roll Forming Machine | Support Frame | Square pipe welded |

| Side Wall | Memorial Archway style | |

| Forming Station | 12 | |

| Structure | Stong and stable | |

| Shaft | 45# high grade steel, CNC finish milling | |

| Roller | Cr12 | |

| Transimission | 1.2inch Chain | |

| Bearing | Standard | |

| Speed | 12-18m/min | |

| Electric Components | Delta / Siemens / Mitsubishi | |

| Cutting Blade | Cr12Mov, quenched 58°-62° | |

| Operation | Touch button | |

| Dimension | 6.5*1.0*1.5M | |

| Weight | 4.5T | |

We also provide Safety Shield, Hydraulic decoiler, Automatic stacker for your better operation. It can save labor, save cost and can guarantee your production line more safer. Above all, it can improve your work efficiency !3. Pictures of Roll Forming Machine: 4. Machine Production Process: 5. Our Customers:6. Good Feedback:7. Packaging & Loading:

Rolling Shutter Door Roll Forming MachineMain body is covered with plastic film and fixed well by wire rope in container;Rollers are painted by rust oil;Spare parts are packed by carton box;We have professional technicians for loading, guaranteed the goods load into container without any damage;Transportation : Machines need one 20/40 feet container to load.8. Related Roll Forming Machines:9. Why Choose Us ?10. FAQ:Q1. Can you manufacture the roll forming machine according to my profile drawing or picture of finished product ?

A: Yes. Our rich experienced technical team can draft the accurate profile drawing, provide the most suitable technical solution for your required roll forming machine.Q2. How can we be assured that you will deliver us quality machine with spare parts ?

A: 1. Customers can come to our factory, or send the technical people to our factory for checking the quality. 2. We can send the technicians to the buyer's factory for the installation of the machine.Q3. What's your payment terms and delivery time?

A: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 30-45 days for delivery.Q4. Do you have after-sales support?

A: Yes, we are happy to provide advice and we also have skilled technicians available across the world.Q5. Do you sell only standard machines?

A: No, most of our machines are customized according to customers specifications, also adopt top brand components.Q6. What will you do if the machine is broken?

A: We provide 18 months free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the roll forming machine.Q7. Can you be responsible for transport?

A: Yes, please tell me the destination port or address. we have rich experience in transporting.Q8. How to visit your company?

A: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour). 2)Fly to Tianjin airport, By high speed train From Tianjin to Cangzhou Xi (0.5 hour).3) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.Thanks for your viewing !Sincerely looking forward to our better and further communication !Your kind inquiry will be highly appreciated, warmly welcome contact us now !

Prev: Curving Roof Panel Cold Metal Sheet Roof Building Roll Forming Machine

Next: C89 Fully Automatic Light Steel Framing Machine with Software

Our Contact

Send now