Low Price 230-300MPa Strength PPGI Roofing Sheet Crimping and Curving Machine

Description

Basic Info

| Model NO. | NB-1220mm |

| After-sales Service | Whole Life After Sale Serive |

| Warranty | 3 Years Gurantee |

| Tile Type | Colored Steel |

| Certification | CE, ISO |

| Condition | New |

| Customized | Customized |

| Usage | Roof, Wall, Floor |

| Transmission Method | Machinery |

| Color | Green/Blue/Yellow/as Client Like |

| Woking Speed | 0-15m/Min |

| Drive Style | Gear Box / Gear / Chain |

| Raw Material | PPGI/PPGL/Gi/Gl/Alumunium |

| PLC | Orignal Taiwan Delta/Siemens/ Schneider |

| Base Frame | 350h/400h/500h Steel Beam Weld |

| Decoiler | Manual Type 5t Capacity with Brake System |

| Cutting Type | Eletrical Motor Drive/Hydrualic Type |

| Cylindar | Hob High Strengthen |

| Guarantee | 2 Years |

| Power | 11kw |

| Motor | Shanghai Lichao Brand |

| After-Sale-Service | Online 24hours/Field Support |

| Hydraulic System | 4.0kw Motor with Cooling Fan |

| Side Plate | 18/20/22mm Thickness |

| Transport Package | Plastic Packing & Wooden Case Packing |

| Specification | 8000*1600*1000mm |

| Trademark | Noble |

| Origin | Hebei, China |

| HS Code | 8455221000 |

| Production Capacity | 500sets/Year |

Product Description

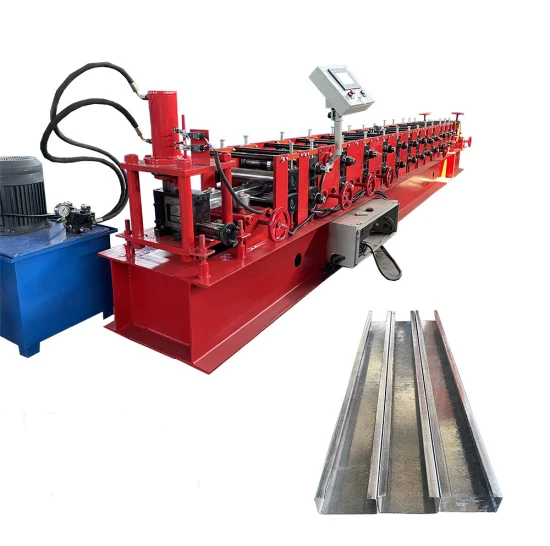

High Quality Automatic Metal Roofing Panel Crimp Roof Curving Arch Bending Roll Forming Machine

Usually Automatic Metal Roof Panel Crimp Roof Panel Curving Roll Forming Machine is used with metal roofing sheet roll forming machine, In some places we need different shape roof sheet,so we need Automatic Metal Roof Panel Crimp Roof Panel Curving Roll Forming Machine to make curved roof sheets such like some building corner.

| . | Roof Curving Roll Forming Machine | |||

| 1 | Suitable to process | Color alu-zinc steel roof sheet,galvanized roof sheet,aluzinc roof sheet | ||

| 2 | Roller | 3Rows based on design | ||

| 3 | Dimensions | 2.6*1.5*1.6m | ||

| 4 | Motor Power | 3Kw | ||

| 5 | Pump Station Motor | 3Kw.Lichao Brand | ||

| 6 | Thickness of the plate | 0.3-0.8mm | ||

| 7 | Productivity | 3-5m/min | ||

| 8 | Material of the cutting blade | Cr12,Quenched treatment 58ºC-60ºC | ||

| 9 | Diameter of the roller | Φ70mm | ||

| 10 | Weight | About 2450kgs | ||

| 11 | Main structure of the machine | 350H beams | ||

| 12 | Processing precision | Within 1.0mm | ||

| 13 | Side panel of machine | 16mm | ||

| 14 | Chain Wheel and Cycle Chain | 1 Inch | ||

| 15 | Voltage | 380V 50Hz 3phases or as customer's need | ||

| 16 | Control system | PLC control (Delta) | ||

| 17 | Frequency system | Delta | ||

| 18 | Drive mode | Motor driver | ||

| 19 | Touch screen | Delta | ||

| 20 | Rolling materials | 45# forging steel with chromium plate | ||

| 21 | Length Tolerance | ±2mm | ||

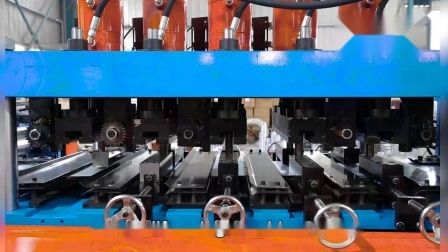

Side wall thickness: Q235 t30mm ;

Roll Station :5 Rows

All the screw bolts with grade 8.8

Post Hydraulic Cutting Device Post to cut, stop to cutting,Three pieces type of cutting blade design, no blanking

Hydraulic motor:5.5 KW ;

Cutting tool material: Cr12MoV

The cutting power is provided by the main engine hydraulic station

Feeding Part :

Product feature

1 More efficient and accurate execution of production orders;

2. High equipment reliability;

3. Little waste of materials and energy;

4. High productivity;

5. High quality materials, get a longer service life;

6. All parts of the machine are processed with precision, and the surface of the roll is chromeplated to ensure that customers can get qualified products at the same time, it can avoid the scratch of the color steel surface paint, and increase the service life of the roll;

7. Customized coil processing solutions to solve all aspects of technical problems.

1 More efficient and accurate execution of production orders;

2. High equipment reliability;

3. Little waste of materials and energy;

4. High productivity;

5. High quality materials, get a longer service life;

6. All parts of the machine are processed with precision, and the surface of the roll is chromeplated to ensure that customers can get qualified products at the same time, it can avoid the scratch of the color steel surface paint, and increase the service life of the roll;

7. Customized coil processing solutions to solve all aspects of technical

Why Choose this machine?

1. Lifetime seivices

2. Introduced Mitsubishi PLC with touch screen to machine controll system.

3. One worker operation (minimum)

4. Lifetime>10years: roller cover with 0.05mm chrome

72mm diameter solid steel shaft

Cutting blade with heat treatment.

5. Cr12 mould steel cutter with quenched treatment.

6. Product cut-to-length.

8.Technician overseas installing and training availableAfter Sales Service

1. Engineer will give free training lessons to labors in buyer's factory. 2. The Buyer need buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for engineer. 3. During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by incorrect operations, we will provide the buyer spare parts at cost price. 4. We will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide

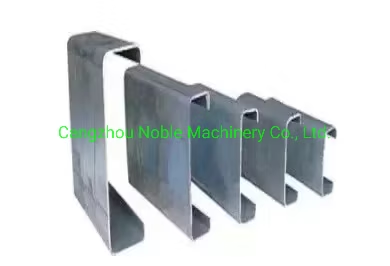

Packaging & Shipping

Our company Sell machinery from 2011 years, manufacture all kind of machinery: Roof Tile machinery, wall panel machinery, roofing corrugated sheet machinery, floor deck machine, C&Z Purline machine, highway guardrail machine, EPS/Rock wool Sandwich panel line, Container board machine, Roll shutter door machine, Down spout machine and Steel bar straightening machine, PPGI/GI/GL Coils, Prefabricated container house Etc. All our clients are satisfied with the workmanship and performance of our machines because our company is accompanied with sound infrastructure and qualified team, Our company prime mission is to provide superior quality industrial machines that are efficient, highly productive and durable.

All our efforts are resulted in to the growth at par excellence and also company started getting recognized as an organization compassionately devoted to the policy of "Quality" with "VALUE FOR MONEY".

Exhibition & Client Visit

.How to play order :

Inquiry---confirm the profile drawings and price---confirm the PI---arrange the deposit ---we start producing

What can we do if the machine broken?

The machine will be tested before shipment with coil, ensure everything is ready 2.We will prepare some spare parts along with the machine, ensure our customer can solve the issue in a shortest time.Both the sale person and technician can give you the service overseas and make training for the workers,the sale person can make translation, so that the installation and training will be more clear and easily.

Guarantee

Lifetime maintenance guarantee.We offer 2 years guarantee

*After-sales

To give you the best after-sales service, the first give you video call with professional technicians , the second we send technicians to your country to repair the machine,The buyer shall bear all expenses, including visa, round-trip airfare and suitable accommodation, and pay the salary of usd 100 / day.

.Contact us:

If you want to get more pictures or videos of the machines, feel free contact us.We will give you the best experience! Website:noblemachine.en.made-in-china.comFactory Address:105 National Road, Botou , Cangzhou City , Hebei Province, China

Prev: Galvanized Metal Sheet Light Furring Channel Steel Keel Framing Machine

Next: Curving Roof Panel Cold Metal Sheet Roof Building Roll Forming Machine

Our Contact