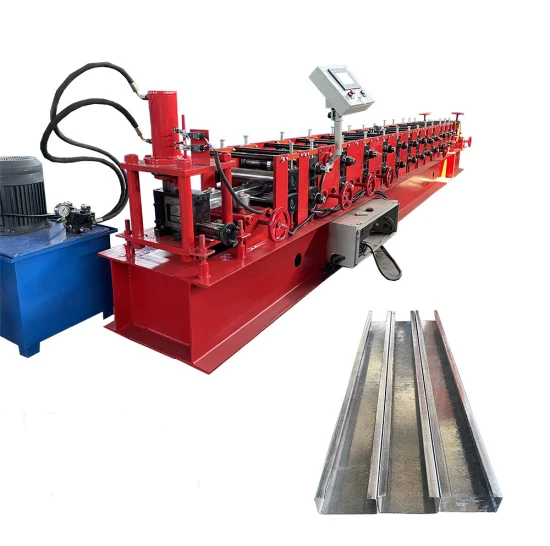

Metal Roofing Galvanized Aluminum Corrugated Steel Sheet Making Machine

Galvanized Corrugated Roof Sheet Making Machine with CE Factory Lifetime Service! one machine can make two different des

Description

Basic Info

| Model NO. | 836 corrugated sheet machine |

| Tile Type | Colored Steel |

| Certification | ISO9001: 2000, Ce |

| Condition | New |

| Customized | Customized |

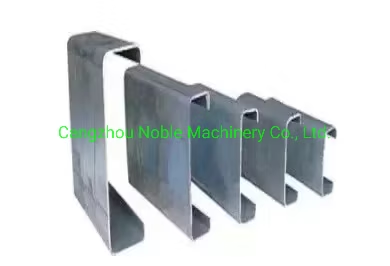

| Usage | Roof, Wall, Floor, Structure |

| Transmission Method | Machinery |

| Use | Roof |

| Color | Blue |

| Suitble Material | Galvanized Steel, Aluminum |

| Power | 4+4kw |

| Voltage | Customerized |

| Speed | 10-15m/Min |

| Mateiral Thickness | +0.18mm |

| Color of Roll Forming Machine | Blue |

| Shaft of Machine | 75mm |

| Transport Package | According to Customers′ Request |

| Specification | CE/SGS |

| Trademark | JCX |

| Origin | China Hebei |

| HS Code | 845221000 |

| Production Capacity | 40sets Per Month |

Product Description

Galvanized Corrugated Roof Sheet Making Machine with CEFactory Lifetime Service!

one machine can make two different design,if your workshop space is limited,double layer roll forming machine is your best choice.

Metal Roofing Sheet Corrugating Iron Sheet Roll Forming Making Machine Cold Galvanizing Line with ISO9001/Ce/SGS/Soncap

Why choose this Machine?

1. Designed by 15 years experienced R&D members

2. Introduced Mitsubishi PLC with touch screen to machine controll system.

3. Need only one worker (minimum) to operate

4. Roller cover with 0.05mm chrome, ensure lifetime>10years

5. Cr12 mould steel cutter with quenched treatment. Blade with heat treatment.

Improved structure, more stable cutting performance.

6. Product cut-to-length.

7. 72mm diameter solid steel shaft

Technician can be sent to your factory to install the machine and train your workers

Technical data

| Suitable material | Q235 color steel sheet; 0.3-0.7mm, |

| Forming speed | about 15-20m/min |

| Power Requirement | Main motor power: 7.5 Kw(Depend on final design) |

| Hydraulic station power: 2.2Kw(Depend on final design) | |

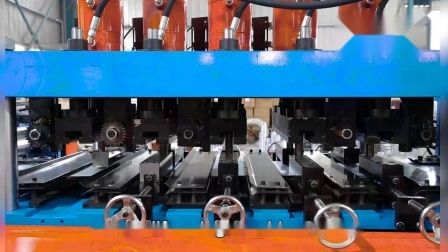

| Material of forming rollers | No.45 steel, plated with chrome on sureface. |

| Material of cutter | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. |

| Roller grinder milling. | |

| Shaft diameter | 72mm |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 8000KGS |

| Machine's size | about 9m×1.5m× 1.5m (Depend on final design) |

Components

| Decoiler (manual/ hydraulic decoiler for option) | 1set | |

| Feeding & guiding device | 1set | |

| Main roll forming machine | 1set | |

| Hydraulic cutting system | 1set | |

| Controlling system | 1set | |

| Run out table (auto. Stacker for option) | 1.5m/ pc, 2 pcs | |

Process flow:

Decoiler -- Feeding & Guiding -- Roll Forming-- Hydraulic Cutting - Product to Run Out Table

Packing:

1. One 40feet container for loading one set machine with mechanical decoiler.

2. Main machine body and decoiler is load naked (tighten to container with steel wire rope).

3. Spare parts and operating tools are loading in tooling box.

Prev: Xn Cold Steel Corrugated Iron Sheet Roofing Tile Making Roll Forming Machine

Next: Main Ridge Tile Endcap Main Ridge Tile Tilted Ridge Tile Tee 3-Way Synthetic Resin Roofing Accessory

Our Contact

Send now