Yx25-210-840 PU Sandwich Panel Roll Forming Machine

Description

Basic Info

| Model NO. | Yx25-210-840 |

| Tile Type | Glazed Steel |

| Certification | CE, ISO |

| Condition | New |

| Customized | Customized |

| Usage | Roof |

| Transmission Method | Hydraulic Pressure |

| Working Material | Galvanized Sheet(Gi), Cold Roll Steel(CRC), Hot Roll |

| Thickness | 0.3-0.6mm |

| Yield Strength | 245-345MPa |

| Foaming Paper | Width 900mm PVC Paper |

| Heating System Motor | 30kw |

| Foaming System Motor | 4kw |

| Air Pressure | 7pH |

| Output | About 12meters Per Minute |

| Main Motor | 7.5kw |

| Transport Package | Naked and Covered by Plastic Film Into Container |

| Specification | About 17.0M*2.2M*2.4M |

| Trademark | BMS |

| Origin | China (Mainland) |

| HS Code | 8455221000 |

| Production Capacity | 30sets/Month, 12-15m/Min |

Product Description

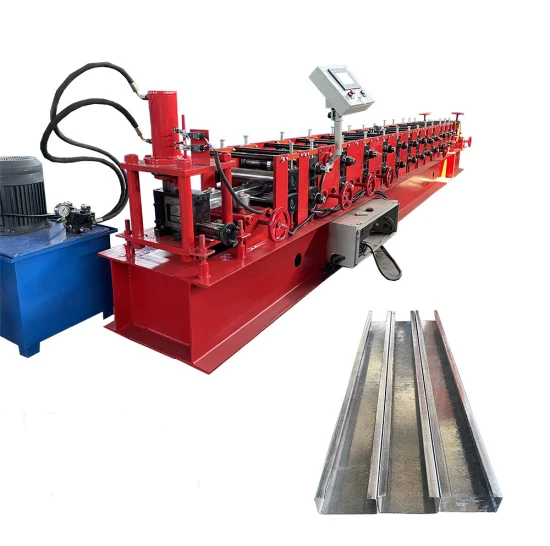

Yx25-210-840 PU Sandwich Panel Roll Forming Machine

Product Description

1. Details of PU Foaming Machine

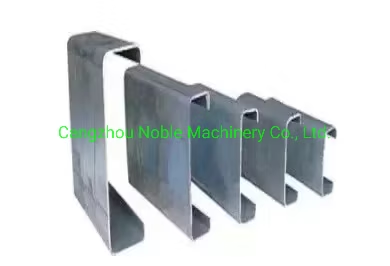

| Material |

| Material Thickness(&):0.3-0.6mm |

| styrene foam: Isocyanate A material (black material), Combined polyether B material (white material) |

| Foaming Paper: width 900mm, PVC Paper |

| Applicable material:Galvanized Steel Coils, Hot Rolled Coils,Cold Rolled Coils,yield strength 245Mpa or 550Mpa |

| Machine Components |

| 1)Manual Decoiler: one set |

| Max. feeding width: 500mm, coil ID range 470mm±30mm |

Capacity: Max. 3Ton |

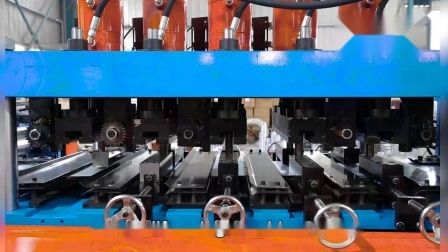

| 2)Cold Rolling Mills: |

Rollers manufactured from bearing steel GCr15,precision machined,hard Chrome Coated with thickness 0.04mm(for longer life and anti-rust) ; |

Motor Driving,Gear chain transmission, 18 forming stations and 7 rollers(3 upper rollers and 4down rollers)for straightening and levelling) |

| Main Motor=5.5KW , Frequency speed control |

| Forming System Motor capacity: 4KW |

| Heating System Motor capacity: 30KW |

| Forming speed approx.8-13m/min |

| 3)Cutting tool material: Cr12, Heat treatment |

| 4)PLC Control System(Touch screen brand:Taiwan WEINVIEW,Inverter brand:Finland VOCAN/Denmark Danfoss ,Encoder brand: Japan Koyo) |

| Control the quantity and cutting length automatically |

| Combined with: PLC, Inverter, Touch Screen, Encoder, etc |

| Cut-to-length tolerance≤±1mm |

| Control Voltage 24V |

| 5) Exit Rack Un-powered, two units |

2. Machine Features of PU Foaming Machine

The advantages of metal roof panel cold roll forming machineare as follows:1.Assembly process meets export standards, body frame and sideboard are spray-painted, other parts are finished through baking/chroming/galvanizing/blackening respectively, then unified assembly. After surface treatment,not only extend lifetime, but also improve overall appearance. 2.Manufactured from 45# steel, CNC lathes, Heat Treatment, hard Chrome Coated,surface with mirror treatment (more wearable and rust-free) 3.Easy operation, low maintenance cost

3. Detailed Images of PU Foaming Machine

Machine Parts

Name: Shaft

Brand: BMS

Original: China

Machine Parts

Name: PLC control system Brand: SIEMENS/SCHNEIDER ELECTRIC Original: Germany/France Combined with: PLC, Inverter, Touch Screen, Encoder, etcEncoder: KOYO/Omron (Japan brand)

PLC Control SystemControl The Quantity And Cutting Length AutomaticallyInput The Production Data(Production Batch,pcs,Length,etc.)On The Touch Screen ,It Can Finish The Production Automatically.

| Combined With | PLC, Inverter, Touch Screen, Encoder, etc |

| PLC | Siemens (German brand)/Schneider(French brand) |

| Inverter | Siemens (German brand)/Schneider(French brand) |

| 7-Inch Color Touch Screen | Siemens (German brand)/Schneider(French brand) |

| Encoder | Omron (Japan brand)Switch Bottom, Indicate Light, Power Supply, Intermediate Relay, AC Contactor |

| Thermal Relay | Siemens(German brand)/Schneider(French brand) |

| Air Switch | LG-LS(Korea brand)Cut-to-Length Tolerance≤±1 mmControl Voltage 24V |

After-Sale Service1. The warranty is 24 months after the client receives the machine.Within The 24months, we will courier the replacement parts to the client free of charge2.We offer technical support for the entire life of our machines3. We can send our technicians to install and train the workers in the clients' factories with extra costTerms Of Trade

| Minimum order quantity (MOQ) | 1 Set |

| Delivery time | about 45 workdays |

| Port of loading | port of Xiamen |

| Type of payment | by T/T or by L/C |

| Export | to more than 80 countries and regions, including South Korea,Taiwan, UK, Ireland, Greece, Australia, USA, Mexico, Brazil, Russia,Saudi Arabia, UAE, Iran , India, Singapore, Malaysia, Thailand,Indonesia, Philippines, Vietnam, South Africa, Nigeria, Egypt, etc |

Packing Style

| Packing method | Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),loaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation. |

View more products,click here...

Company Profile

Prev: Factory Direct Sales Rolling Shutter Door Forming Equipment Cold Bending Machine

Next: Good Price Rolling Shutter Door Make Roller Shutter Forming Machine

Our Contact