Standing Seam Roof Curving Machine Bending Machine

Description

Basic Info

| After-sales Service | Life Long Tracking Service |

| Warranty | 2 Years |

| Tile Type | Colored Steel |

| Certification | CE, ISO, SGS |

| Condition | New |

| Customized | Customized |

| Usage | Roof, Wall, Floor |

| Transmission Method | Hydraulic Pressure |

| Material | Gi/PPGI/Aluminum |

| Control System | PLC(Imported Brand), Servo, Hydraulic System |

| PLC Brand | Panasonic /Mitsubishi |

| Name | Standing Seam Metal Roof Bending Curving Machine |

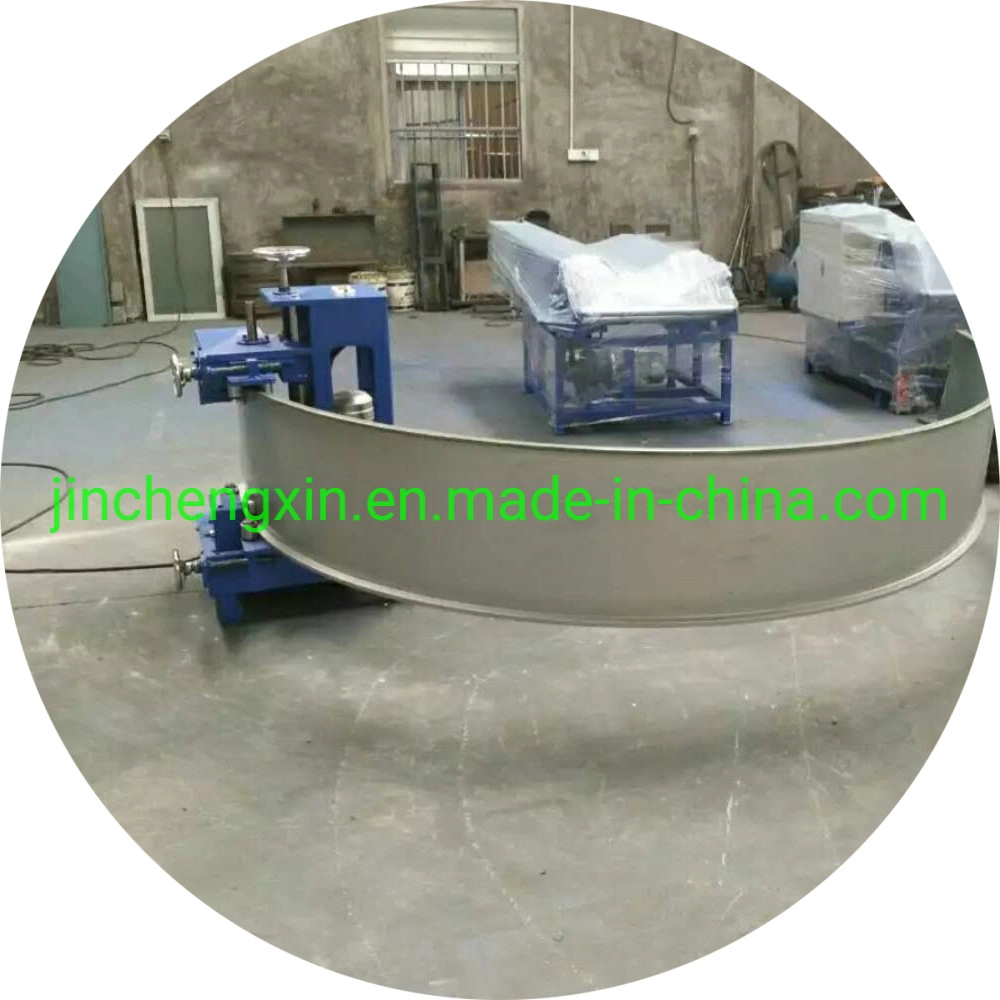

| Arcing Shape | Regular Arc, Regular and Anti-Arc, Anti-Arc. |

| Forming Thickness | 0.6-0.9mm |

| Bending Panel Type | Straight Panel, Fan-Shape Panel |

| Bending Straight Panel | Min Width: 300mm, Max Width: 720mm |

| Roller Materials | CNC S45c Steel and Bearing Steel Gcr15 |

| Transport Package | According to Customers′ Request |

| Specification | Standing Seam Metal Roof Bending Curving Machine |

| Trademark | JCX |

| Origin | China Hebei |

| HS Code | 8455211000 |

| Production Capacity | 40sets Per Month |

Product Description

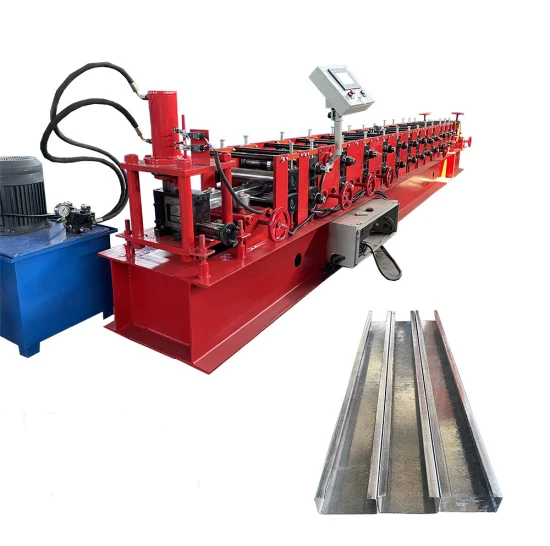

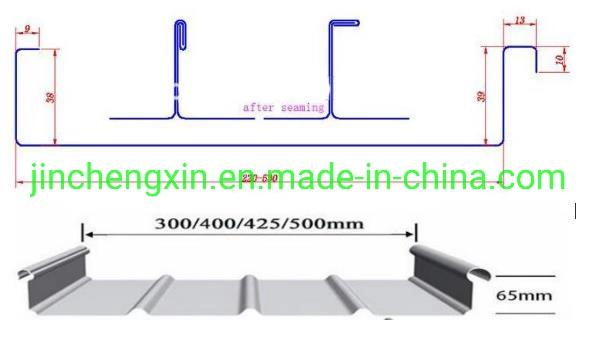

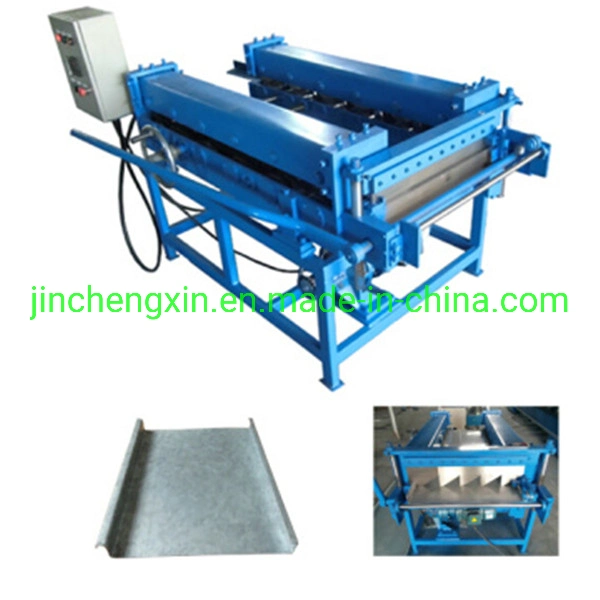

Standing seam roof curving machine bending machineThe Standing Seam Metal Roof Bending Curving Machine for Straight & Tapered Panel is used to bending and curving the unexposed screw roof sheet.

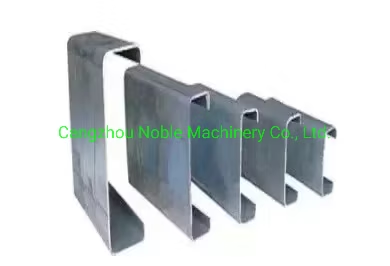

Firstly, the standing seam roof panels have a concealed fixing or seaming method by turning up the edges of two adjacent panels, and then folding or interlocking them. In this way, the seaming or fixing parts are invisible, and therefore sometimes we called the panels concealed fixing panels!

The material thickness varies from 0.4-0.8mm,in some places such as USA,they use copper as raw material. But some other concealed fix standing seam roofing, like bemo roof sheet are thicker from 0.8-1.2mm.

1. Main Technical Parameters of Standing Seam Metal Roof Bending Curving Machine for Straight & Tapered Panel:

1.1 Main components of Standing Seam Metal Roof Bending Curving Machine for Straight & Tapered Panel:

No. | Name | Quatity |

3.1 | Decoiler | 1 set |

3.2 | Main Forming Machine | 1 set |

3.3 | Support Table | 3 sets |

3.4 | Bending Machine | 1 set |

3.5 | Conventional tools | 1 set |

3.6 | Operation instruction | 1 piece |

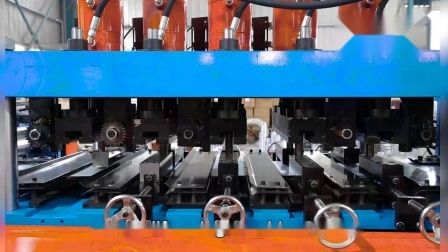

1.2 Main Machine parameters of Standing Seam Metal Roof Bending Curving Machine for Straight & Tapered Panel:

Main Technical Parameters Of Bending Machine | |

Motor Power | 1.1KW |

Pressing Thickness | 0.6-0.9 mm |

Wheel Gear Box | Vertical gear reducer |

Forming Material | PPGI |

Type Of Transmission | By chain |

Applicable Panel | 220-530 Straight Panel And Sector Panel |

Forming Stations | 4 |

Adjusting Way | Manually adjust the front and back arcs,radius size |

Roller Materials | CNC S45C Steel with hard chrome coating |

Size of positive arc | The following instructions |

Size of anti-arc | The following instructions |

External Dimension | About 0.5m×0.8m×1.1m |

Electric Control | Simple switch control |

Weight of machine | About 300KG |

Working Voltage | 380V 50HZ 3 Phrase |

Standing Seam Metal Roof Bending Curving Machine for Straight & Tapered Panel

2. Design of Standing Seam Metal Roof Bending Curving Machine for Straight & Tapered Panel:

3. Our Service:

1. We provide the technical support for whole life of self lock standing seam roof roll forming machine.2. Meanwhile, if any parts go broken and not artificial damage, we will send you new ones for free. 3. When need the technician to go abroad, we will arrange the technician.

4. Galvalume Portable Standing Seam Roofing Panel Roll Former:

Prev: 1 Inch Standing Seam Panel Curving Machine 1" Roof Panel Curving Machine

Next: Fully Automatic Portable Standing Seam Curving Machine Arching Machine

Our Contact