Reliable Joint Hidden Standing Seam Metal Roofing Roll Forming Machine

Overview Reliable joint hidden standing seam metal roofing roll forming machine Product Description Detailed Photos Cert

Description

Basic Info

| Model NO. | Customized |

| Usage | Roof |

| Transmission Method | Electric |

| Suitable Material | PPGI/PPGL/Gi/Gl |

| Suitable Thickness | 0.3-0.8mm |

| Profile Drawing | Customized |

| Voltage | as Customer′s Request |

| Speed | 15-20m/Min |

| Delivery Time | 40-60 Days |

| Loading Method | FCL |

| PLC | Delta |

| Touch Screen | Touch Win |

| Encoder | Omron |

| Inveter | Saj |

| Electric Components | Delixi or Chnt |

| Driving Motor | Lichao |

| Hydraulic Motor | Lichao |

| Transport Package | Export Package |

| Specification | 20GP |

| Trademark | FWD |

| Origin | China |

| HS Code | 8455221000 |

| Production Capacity | 30 Sets/Month |

Product Description

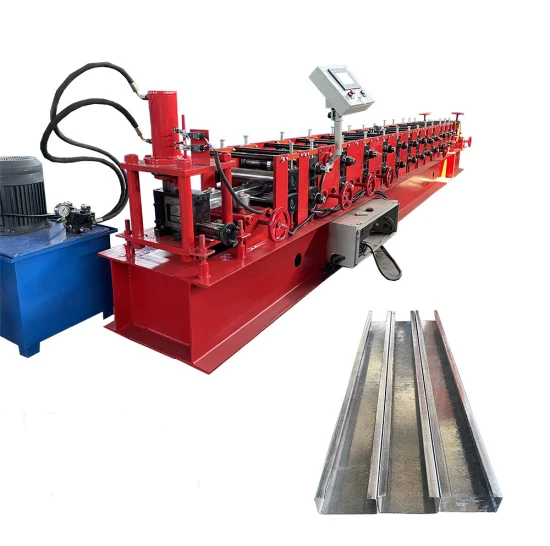

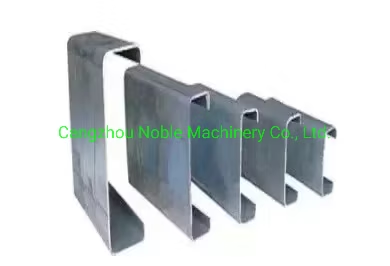

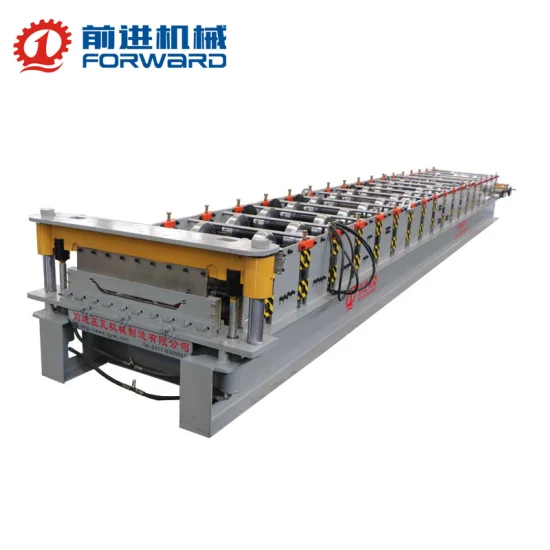

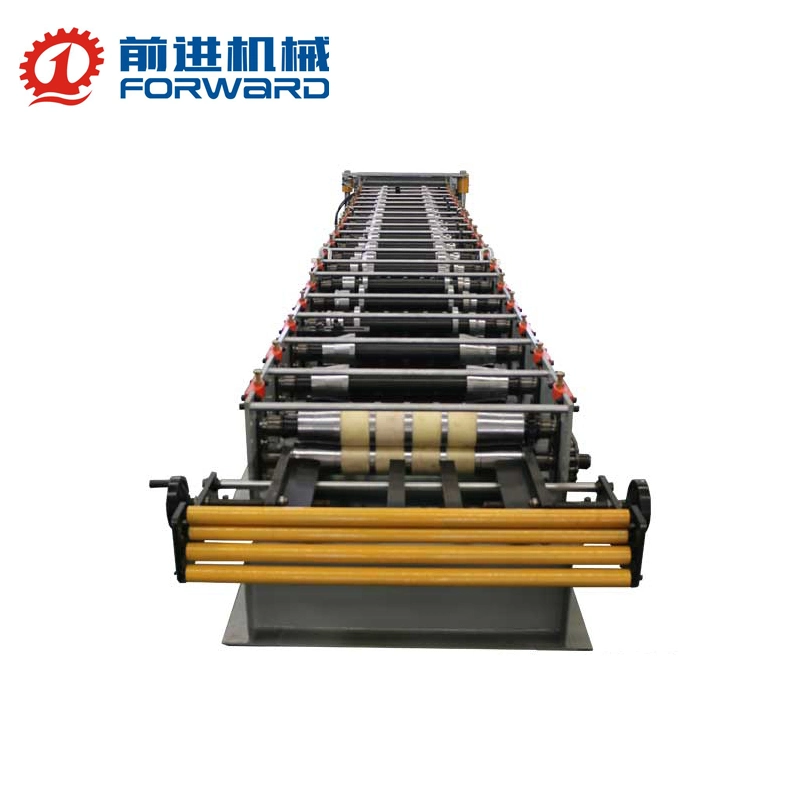

Reliable joint hidden standing seam metal roofing roll forming machine

Product Description

| General Information | Coil Material | PPGI/PPGL/GI/GL |

| Coil Thickness | 0.3~0.8MM | |

| Coil Width | 1000MM | |

| Speed | 15~20M/MIN | |

| Voltage | As Customer's Request | |

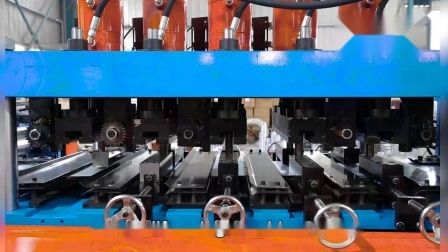

| Roll Forming Unit | Roller Station | 18 |

| Driving Motor | 7.5KW | |

| Shaft Diameter | 70mm Solid | |

| Shaft Material | 45# Hard Steel | |

| Roller Material | 45# Hard Steel | |

| Under Frame | 350H-Beam | |

| Sidewall Thickness | 16MM | |

| Transmission | 1 Inch Chain | |

| Feeding Device | 1 Set With Pre-cutter | |

| Cutting Unit | Cutting Type | Hydraulic Stop TO Cut |

| Hydraulic Pump Power | 3KW | |

| Cutting Die Material | Cr12Mov | |

| Hydraulic Oil | 46# Abrade Oil | |

| Control Unit | Control Method | PLC |

| Length Control | Encoder | |

| Operation | Touch Screen | |

| Language | Chinese & English | |

| Auxilliary Device | --- | 3T Manual Decoiler |

| --- | Exit Rack | |

*All parts can be customized as customer's request. | ||

FAQ

Q1. What are the main key points for selecting right machines?

A1: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that pricenot the final point.

Good quality is for long-term business cooperation.

Q2. Can you provide OEM service for roll forming machine?

A2: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production

usage, machine speed, then machine specification will be some different.

Q3. What's your standard trade terms ?

A2: We can provide the technical offer with FOB,CFR,CIF,Door to Door and so on. Please kindly tell the detailed port name for

competitive ocean freight.

Q4. How about the quality control?

A4: Our company adopts 6S system to control every part with passed ISO9001:2000, CE,TUV/BV(Alibaba) Certificate.

Q5. How about the after-sale service?

A5: We provide 18 months free warranty and free technical support for the whole life of any machine. During warranty period, if

parts still broken, we can send the new ones freely.

Q6. If I am in Beijing,Shanghai or Guangzhou,how to visit your company?

A6: 1) Beiing South Statioin to Cangzhou West Station (by fast train 1 hour).

2) Shanghai Hongqiao to Cangzhou West (4.5 hours)

3) Guangzhou Airport to Tianjin ,then Tianjin to Cangzhou West

Prev: High Speed 77 PU Foam Shutter Slat Door Rolling Making Forming Machine

Next: High Pressure PU Polyurethane Foam Foaming Injection Machine for Sandwich Panels Line

Our Contact

Send now