PU EPS Sandwich Panel Production Line Precast Plastic EPS Concrete Wall Panels Making Machine

Package size per unit product 34.00cm * 55.00cm * 50.00cm Gross weight per unit product 1000.000kg eps sandwich panel pr

Description

Basic Info

| Model NO. | EPS sandwich wall panels |

| Automatic Grade | Automatic |

| Power Source | Electric |

| Screw Design | Double-Screw |

| Certification | CE, ISO |

| Condition | New |

| Customized | Customized |

| Transport Package | Container |

| Specification | customized |

| Trademark | Hongfa |

| Origin | China |

| HS Code | 8474802000 |

| Production Capacity | 51000 |

Packaging & Delivery

Package size per unit product 34.00cm * 55.00cm * 50.00cm Gross weight per unit product 1000.000kgProduct Description

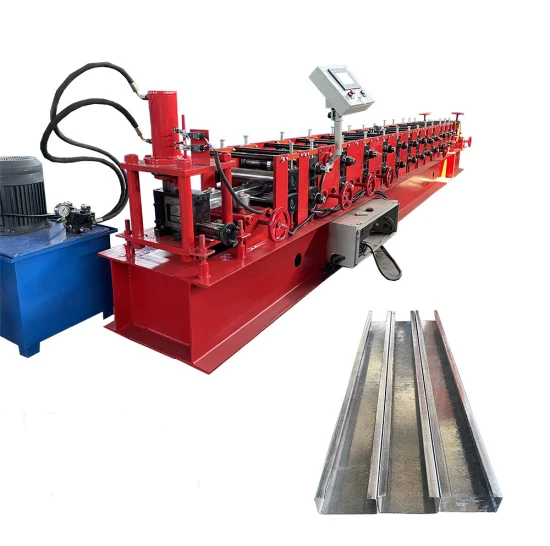

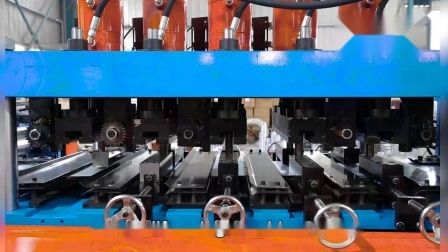

eps sandwich panel production lineWall panel machine introduction of precast plastic EPS concrete wall panels making machine1).The EPS sandwich panel production line adopts PLC and touch screen control, automatic filling,Electronic weighing, temperature control, material level control to realize automatic production.2).With the same machine, it can adjust the panel size and thickness. The thickness will be from60 to 180mm.3).The closed constant pressure foamng barrel features of high heating efficiency and saves stem.4).High precise guiding pressure reducing valve controls the temperature and steam pressure of theClosed barrel, ensuring the outcome pressure of the valve constant and the inner temperatureControlled within±1%, which keeps the foamed material equal and prevents the bead agglomerateBecause of the bad temperature control.5).With photoelectric or vibration sensor to control material level, ensuring density tolerance within ±3%.6).The machine is equipped with fluidized bed dryer, including drying, automatic sieving, depluming andMaterial conveying to silos.7).Most components are of world-famous brands, with reliable performance, stable quality, long serviceLife and low maintenance cost.8).The machine can realize the primary and second expansion

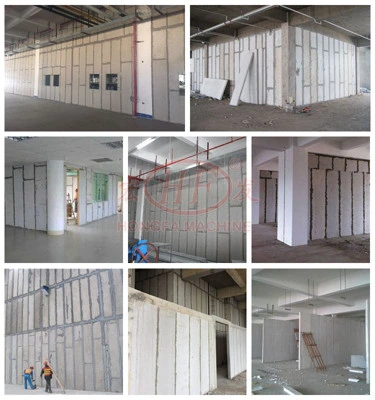

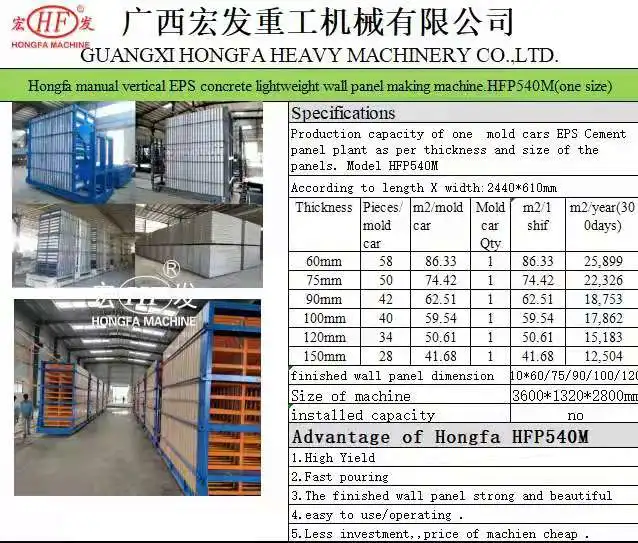

vertical type partition wall board making machine: Manual operation,the highest output amount the three types, but requires more workers.

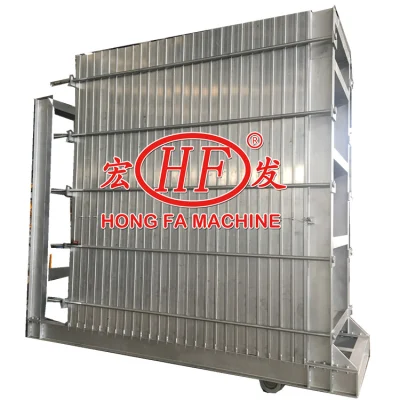

Vertical Manual panels de-molding wall panel production line /EPS GFRG Panels Wall Lightweight Precast Concrete Wall Panel Making Machine Sandwich Panel production Line

This sandwich concrete dry wall panel is in low investment and highest capacity. This kind of sandwich lightweight wall panel machine can be considered due to the limit of functional requirements.

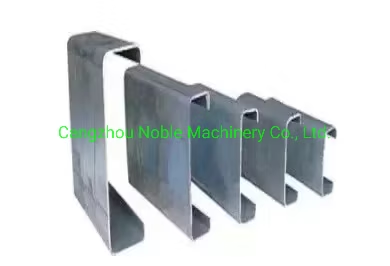

| Manual Vertical Type | |||||||

| Overall dimensions | Power | Output with different thickness/pieces per mold | |||||

| 60mm | 75mm | 90mm | 100mm | 120mm | 150mm | ||

| 3600x1320x2800 mm | no | 58pcs | 50pcs | 42pcs | 40pcs | 34pcs | 28pcs |

Guangxi Hongfa Heavy Machinery Group was established in 1990, is one of the largest block making manufacturer and leading supplier of the building block industry in China,as an ISO9001-2000 certificate and "Famous Brand in Guangxi"enterprise and member of China Building Block Association.

Hongfa Machinery'Honor

1.One of Top Ten Influential Brands in China Brick &Tile Industry

2.China National Enterprice Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protectionb Demonstration Unit

4.High and New Technology Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

Our Contact

Send now