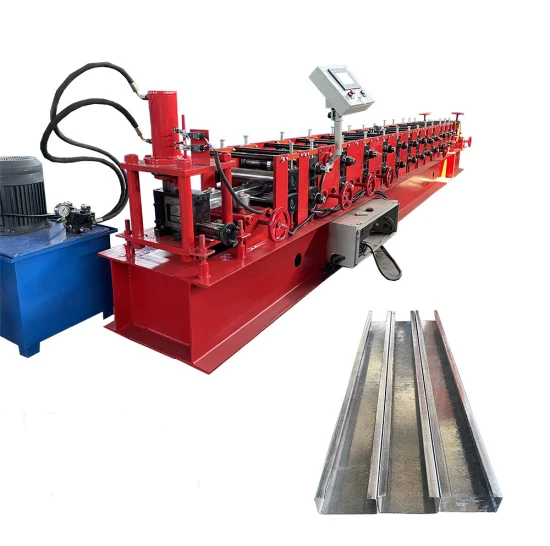

Ibr Trapezoidal Galvanized Roofing Sheet Roll Forming Machine From Botou Factory

Description

Basic Info

| Model NO. | roofing sheet roll forming machine |

| Warranty | 12 Months |

| Customized | Customized |

| Advantage | Use Widely |

| Condition | New |

| Name | Roofing Sheet Roll Forming Machine |

| Material of Frame | 300h Steel |

| Step of Forming Roller | 15steps |

| Diameter of Shaft | 75mm |

| Drive Type of Roll Forming Machine | Drive by Chain |

| Power of Main Motor | 4kw |

| Voltage | 380V/60Hz/3phase |

| Line Speed | About 12 M/Min |

| Motor Power of Hydraulic Station | 4kw |

| Oil Pump of Hydraulic Station | Gear Oil Pump (High Grade) |

| Transport Package | Water-Proof Packaging, Covered with Plastic Film |

| Specification | DX 1000 |

| Trademark | DX |

| Origin | Botou Hebei China |

| HS Code | 84552210 |

| Production Capacity | 20 Set Per Month |

Product Description

IBR Trapezoidal Galvanized Roofing Sheet Roll Forming Machine From Botou FactoryOur products have been sold to worldwide, including North/South America, Asia, Africa, Australia and Europe... We know well about the requirement from different regions' customers.

We have outstanding export team to listen to your request; the designed team will show you the best proposal according to your request.We believe that our cooperation will create bright future.

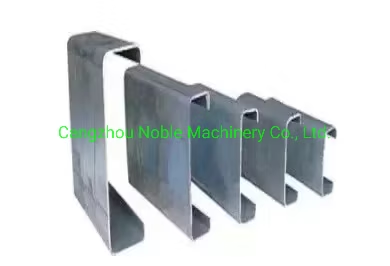

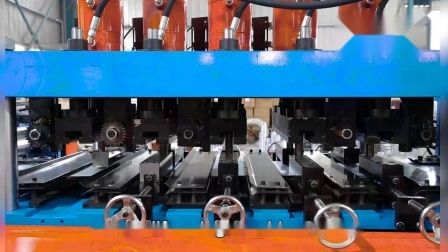

1.Panel drawing according to your request 2.Some machine pictures for your reference.

3. Technique parameters of the processing line

| 1.Processing material | aluzinc/galvanized steel/colored steel coil |

| 2.Material thickness | 0.3-0.8mm |

| 3.Feeding width: | 1000mm or customer request |

| 4.Effective width | 900mm or customer request |

| 5.Main motor power | 4kw |

| 6.hydraulic pump | 4kw |

| 7. Shaft diameter | 75mm |

| 8.Forming steps | 13steps |

| 9.Main frame | 350H Steel frame |

| 10. Side plate thickness | 16mm |

| 11.Roller material | 45# forged steel, with hard chrome plating |

| 12.Control systerm | (Taiwan brand)Delta PLC control system with touch screen |

| 13.Cutting blade material | Cr12 |

| 14.Working speed | About 10-18m/min |

| 15. Transmission way | 1 inch chain drive |

| 16. Machine size (mm) | About 6800*1400*1400mm |

| 17. Machine weight | About 2.5ton |

| 18.Power supply | 380v,3phase,50hz or accodring to customer request |

3. Processing technique and deployment

Manual decoiler- Roll forming machine- PLC system- Hydraulic system-Post cut- Stacking

COMPANY INTRODUCE:

Our enterprise, Cangzhou Dixin Roll Forming Machine , as the professional and leading manufacturer, can manufacture, design, installation and debug various roll forming machines and metal processing sheet equipments, which produce metal roof wall panel, glazed roof tile, CZ steel purlin, floor decking, roof ridge cap, sandwich panel, roof truss, shutter panel, shutter slat, door frame, guardrail, and metal sheet uncoiler, bending, slitting, cutting, flattening, punching, crimping.

Backed by reasonable design, precision machining and selected material, both our standard and customized machines are characterized by long life span, precise forming and easy operation. With our customers' trust, our machines have been sent to America, Australia, Russia, India, Sri Lanka, Nigeria, Pakistan, Uzbekistan, Mozambique, Angola, Turkey, Brazil, etc.

Warmly welcome to China to visit our factory and select the machines you need. Our address, Fuzhuang Industrial Development Zone, Botou City, Hebei Province, China

Why choose us ?

| 1. Installation and training: |

A.If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also trainyour workers/technician face to face. |

| B.Without visiting, we will send you user manual and video to teach you to install and operate. |

C.If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things. |

| 2. after Service |

| A.One year guarantee for whole machine. |

| B.24 hours technical support by email or phone call. |

C.If there is any problem found of the machine, we will repair it for free in one year. |

Customers visit

Packing and shipping details

1. Main body of roll forming machine and decoiler is nude packing.

2. Rollers, shafts, PLC, pump and cutter are packed with water-proof plastic film, spare parts in carton box.

3. One set of machine needs a 20'container to shipping.

FAQ1: How to place order

Inquiry---confirm the profile drawings and price----confirm the PI---arrange the deposit or L/C---then OK

2: How to visit our company

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),

Then we can pick up you.

Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

If any questions, you can call me mobile phone at any times

3: If you want to get more pictures or videos of the machines, I can send them to you by whatsapp.

About Our Roll FormingMachine, If you have any need and questions , please don't hesitate to contact us . at here 24 hours waiting for you . Looking forward to you join us

Our Contact