EPS PU Insert Material Sandwich Panel Making Machine

Description

Basic Info

| Model NO. | FX-EPS |

| Usage | Roof, Wall |

| Transmission Method | Electric |

| Name | EPS PU Insert Material Sandwich Panel Making Machi |

| Shaft | 45# Steel |

| Roller | 45# Steel with Quenching |

| Chain | 1 Inch |

| PLC | Delta |

| Motor | 5.5kw |

| Pump | 4kw |

| Cutting Blade | Cr12 |

| Working Speed | 10-16m/Min |

| Operate Language | as Request |

| Transport Package | Standard |

| Specification | As design |

| Trademark | RFM |

| Origin | Hebei China |

| HS Code | 84552210 |

| Production Capacity | 1000sets/Year |

Product Description

Quick view on EPS PU insert material sandwich panel making machine

| Model Number | FX-EPS |

| Suitable material thickness | 0.25-0.8mm |

| Yield strength | Max 450Mp |

| Machine working speed | 2-3m/min |

| Whole line size | 20*2.5*2.6m |

| Weight | Around 12t |

| Operate language | English and Spanish and Arabic |

| Total power | 30kw |

| Electric wires | 10mm² |

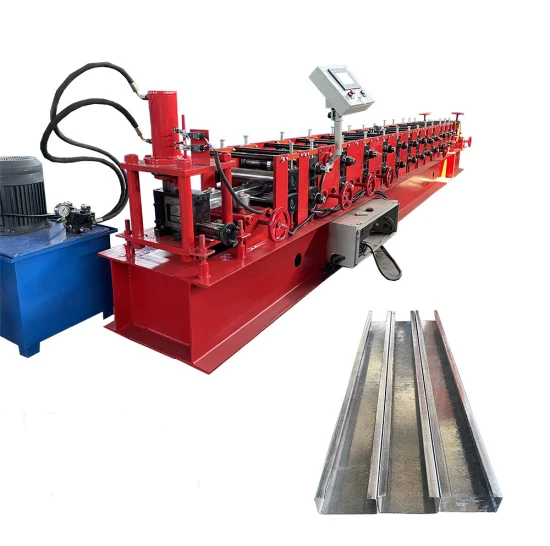

Highlights of EPS PU insert material sandwich panel making machineOne machine for both trapezoidal and glazed sheet producing based on different of material width and thickness,space savingOne motor drive,enengy savingOne control system needs only two workers,labor savingOne cutting susytem, no need change cutting mold,time saving

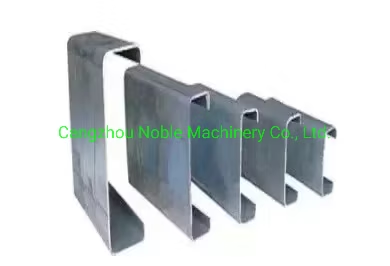

The sheets after roll forming

Product ParametersMachine working flow:

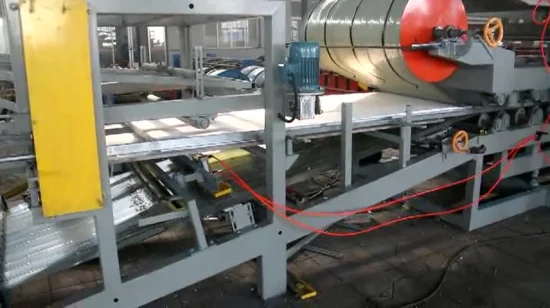

Manual Uncoiler---Feeding Platform---Main Roll Forming---Measuring Length---Computer Control Box---Hydraulic Station Press---Auto Hydraulic Cutting---Products Receiving Table

Technical Specification:

| EPS PU insert material sandwich panel making machine | |

Equipment operation | Automatically |

Voltage | 380V,50/60Hz or at buyer's request |

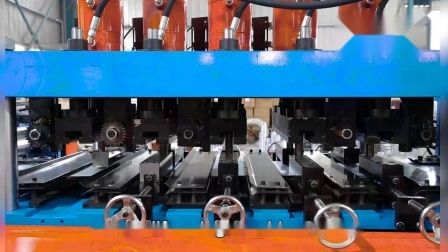

Forming stations | 16 stations |

Width of material sheet | Max 1250mm |

Control system | By PLC(imported brand) |

Cutting method | Hydraulic cutting |

Material of roller station | 45# steel with hard chromed |

Formed width | As drawing |

Shaft diameter | 80mm |

Length of sheet | Just according to your own need |

Transmission type | 1 inch chain |

Manual DecoilerCapacity: 5.0TInner diameter: 450---550mmFeeding platform: which is to support the expand material sheet and help to feed into the main roll forming machineMain roll forming machinePower: 5.5kw or customizedCutting System

Glue spryingTerms Of TradeMinimum order quantity (MOQ) 1 SetDelivery time about 45 workdaysPort of loading port of XiamenType of payment by T/T or by L/CExport to more than 80 countries and regions, including South Korea,Taiwan, UK, Ireland, Greece, Australia, USA, Mexico, Brazil, Russia,Saudi Arabia, UAE, Iran , India, Singapore, Malaysia, Thailand,Indonesia, Philippines, Vietnam, South Africa, Nigeria, Egypt, etcPacking StylePacking method :Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),loaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.For more details,pls check our machine video on line or contact us directly

Company ProfileIntroduction of our company:a. Two decades professional cold steel forming equipments manufacturerb. One comapny with two factory,about 30000 square meter,more than 100 employeesc. National GB/T,CE,ISO9001:2008 Certificated. Built business relationship with customers from more than 65 countries and areas :

Related machinesWe specialized in manufacturing color steel forming machine, C&Z purlin forming machine, Glazed tile forming machine, Steel structural floor panel forming machine, Sandwich panel forming machine, Highway guardrail forming machine and other cold roll forming machines.

Our Contact