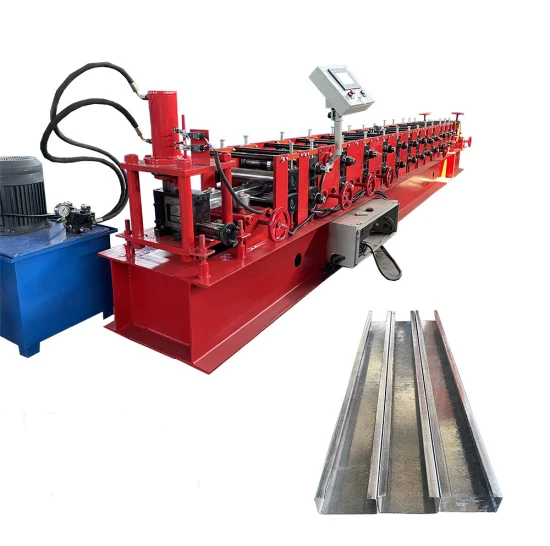

Automatic Australian Style Shutter Door Making Machine Auto Rolling New Type Roll Forming Machine

Description

Basic Info

| Model NO. | Roller Shutter Door Roll Forming Machine |

| Usage | Accessory |

| Transmission Method | Motor Drive |

| Thickness | 0.6-1.0mm |

| Strength | 245MPa |

| Material | Pre-Painted Coil,Galvanized Steel |

| Transport Package | 40gp′*1 (Reference Only) |

| Specification | 11T |

| Trademark | LIMING MACHINERY |

| Origin | Fujian, China (Mainland) |

| Production Capacity | 600 |

Product Description

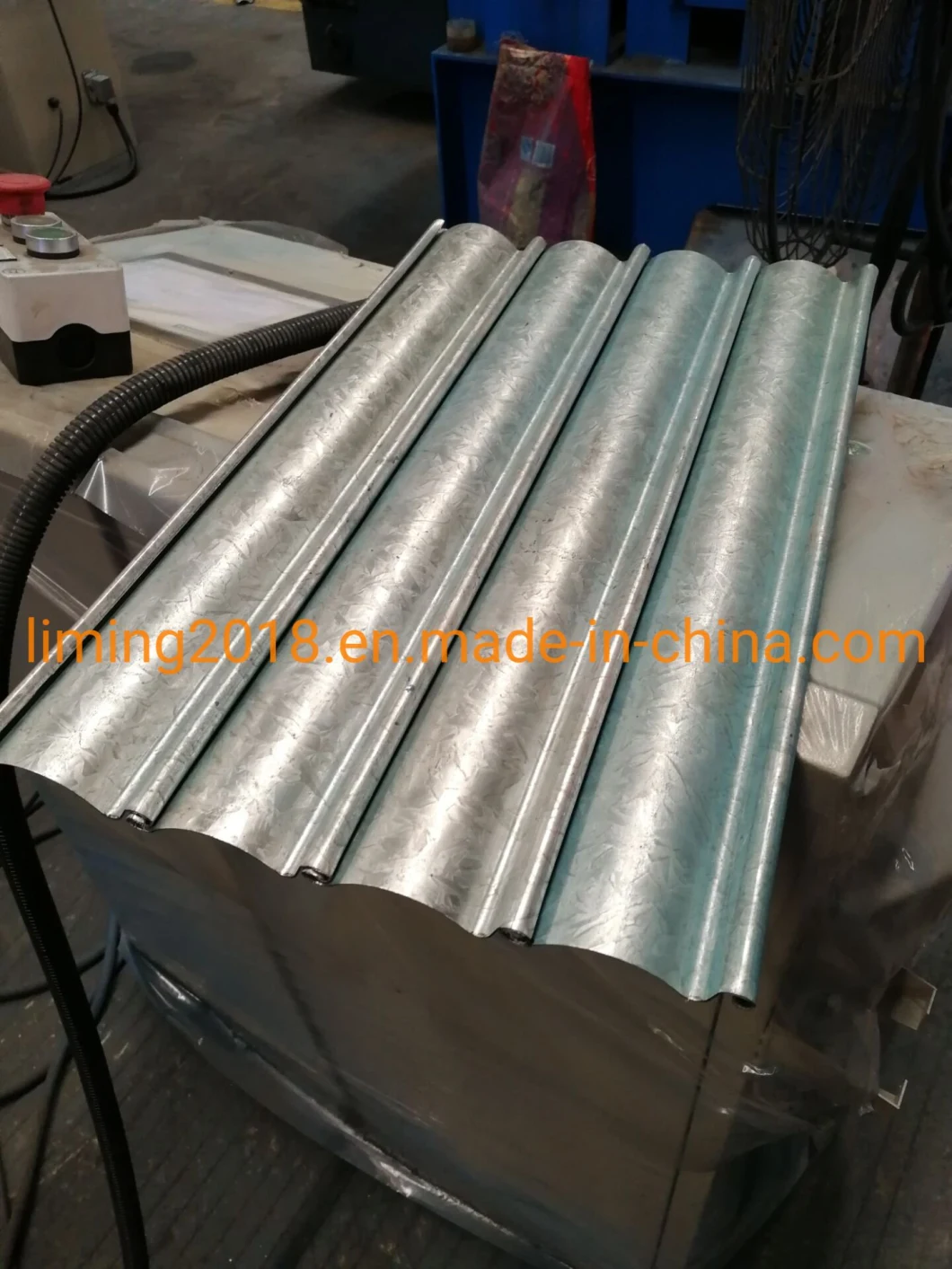

Roll Shutter Door machine

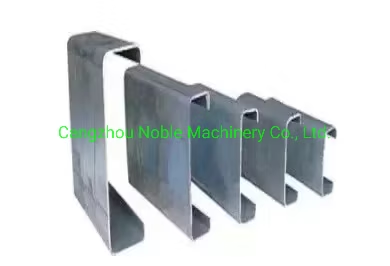

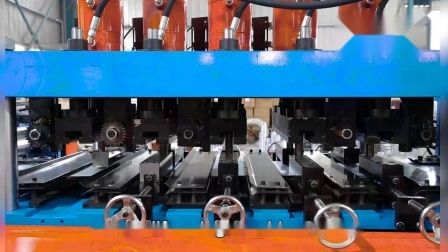

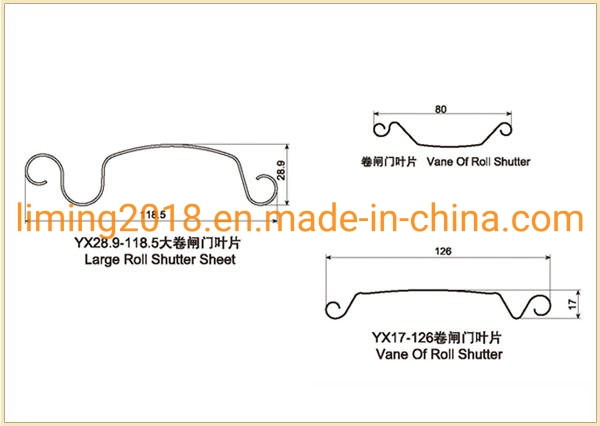

Roller Shutter Door Track Cold Roll Forming Machine is the most popular type of roll forming machines. It makes different shape of roller shutter door slat, which is used in the construction of various roller shutter door, industrial plants, buildings, factory, villages, warehouses, supermarkets, hotels, exhibition, shopping malls, shutter doors and ect. The finished sheet usually worked for roof and wall panel . It has beautiful design, and widely used in all over the world.We adopt export standard technical solution to make machine strong and stable enough. Usually it can run with the normal speed to 15m/min, high speed to 25m/min, max speed to 30m/min. PLC with touch screen operation make the machine simple and easy for operation.The machine is able to produce the steel roll shutter door that used for factory workshop doors and other shop doors. It is convenient for installation, low-noise and easy for maintenance. The sample length is adjust via PLC control system.

Some other popular profiles:

| 1.Suitable material | Color steel sheet , galvanized steel sheet,aluminum sheet |

| 2.Installation Dimension (L*W*H): | 6.5m*1.5m*1.4m |

| 3.Main motor power | 4KW with Cycloidal reducer |

| 4.Hydraulic station power | 5.5KW |

| 5.Thickness of material | 0.6mm~1.0mm |

| 6.Diameter of principal axis | Φ75mm |

| 7.Material of cutting blade | Cr12 ,heat treatment |

| 8.Material expand width | 400-650mm |

| 9.Electric tension | 380V 3phase 50HZ or as the customer's requirements |

| 10.Material of roller | Rollers manufactured from 45# Steel, CNC lathes, hard Chrome Coated |

| 11.Controlling system | PLC |

| 12.Processing speed | 15m/min |

| 13.Roller station | 16 step to form |

| 14. Leak frame load-bearing | 5T |

Below pictures are for your reference only

A: Yes. Our rich experienced technical team can draft the accurate profile drawing, provide the most suitable technical solution for your required roll forming machine. Q2. How can we be assured that you will deliver us quality machine with spare parts ?

A: 1. Customers can come to our factory, or send the technical people to our factory for checking the quality. 2. We can send the technicians to the buyer's factory for the installation of the machine. Q3. What's your payment terms and delivery time?

A: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 30-45 days for delivery.Q4. Do you have after-sales support?

A: Yes, we are happy to provide advice and we also have skilled technicians available across the world.Q5. Do you sell only standard machines?

A: No, most of our machines are customized according to customers specifications, also adopt top brand components.Q6. What will you do if the machine is broken?

A: We provide 18 months free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the roll forming machine.Q7. Can you be responsible for transport?

A: Yes, please tell me the destination port or address. we have rich experience in transporting.

Prev: High Speed Shrinkable Sleeve Seaming Machine, Middle Sealing Machine for PVC, Pet, PETG

Next: Shrink Sleeve Seaming Machine for PVC, PS, Pet, and OPS Sleeve Forming Equipment

Our Contact